Description

In lost-wax casting (rōgata), a wax model is coated with a refractory of sand and clay to produce a mold. The mold is then heated until the wax melts out of it. Next, molten metal is poured into the mold. Once the metal has cooled, the mold is broken open. By melting away the wax, a work of metal may be produced in the exact form of the original wax model.

The lost-wax technique makes it possible to create more complex forms than other types of molds, and the finished pieces have the warm, flowing forms characteristic of wax objects.

Process

- STEP 1

A wax model is made in the desired shape.

- STEP 2

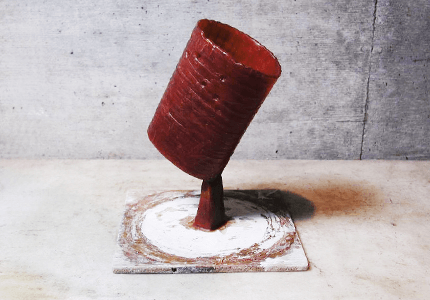

A cylinder is added to the bottom of the wax model to create a channel through which molten metal can be poured into the mold.

- STEP 3

The wax model is enclosed so that refractory can be poured over it to create the mold.

- STEP 4

After melting the wax, molten metal is poured into the mold and the finished piece is removed.