Description

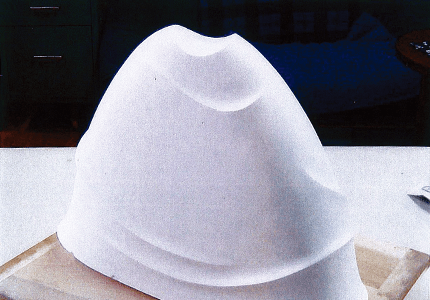

In sectioned mold casting (komegata) a plaster mold is taken from a clay model. The mold is then covered with clay to produce an outer mold, followed by a slightly smaller inner mold.

Molten metal is poured into the space between the outer and inner molds, and the metal is removed from the mold after it cools.

Process

- STEP 1

A plaster mold is taken from a clay model.

- STEP 2

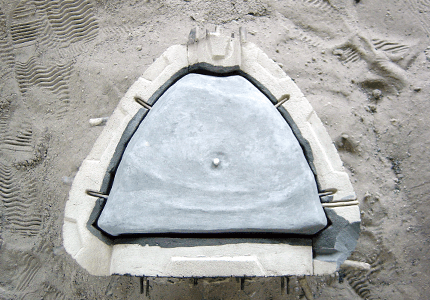

An inner mold is created, leaving a gap for the metal between the inner and outer molds.

- STEP 3

The molds are fired and hardened. Molten metal is then poured into the molds.

- STEP 4

The mold is broken open, revealing a metal piece in the shape of the original clay model.