Description

The material for glass are minerals, also used for pottery, finely crushed. The minerals are mixed with lime and soda ash, and melted and liquefied in a 1200℃ furnace. For colored glass, metal oxide is added and each color is melted in a separate glass melting furnace.

The characteristics of glass are its beautiful transparency where light can shine through, and that the shape can be changed freely.

Artistic Techniques

Blown glass

Blown glass (fukigarasu) is made by applying a gob of molten glass to the end of a stainless-steel tube called a blowpipe. Air is then blown into the tube, inflating the gob like a balloon and making it possible to manipulate the glass into various forms. The finished glass is placed in an annealing furnace and slowly cooled.

Kiriko cut glass

Kiriko cut glass is made by using rotating grinders or diamond wheels to cut geometric patterns and curves into the surface of finished glass vessels. The patterns are evened and finished with fine polishing stones. Edo kiriko and Satsuma kiriko are especially famous.

Copper wheel engraved glass

Designs are engraved into the surface of a glass vessel using small, copper engraving wheels. The copper engraving wheels are spun on a lathe and coated with grease and an abrasive grit or slurry. Using this technique, glass can be freely embellished with plants and animals or other motifs.

Pâte de verre

Pâte de verre (French, “glass paste”) is made by first taking a plaster mold of a clay model. Next, glass powder is mixed with a special binding agent to create a paste. The resulting paste is put into the plaster mold and fired.

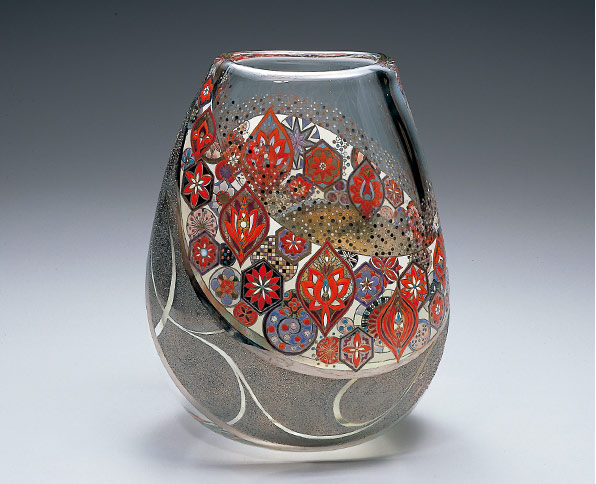

Enameled glass

Designs are painted onto the surface of a glass vessel in enamel. Then the piece is fired in an electric furnace at a low temperature of around 600℃. Fired enamel displays a beautiful, glossy sheen.